Kaolin clay excavation

Clay mine

Kaolin clay

Kaolin Clay excavation

Kaolin Clay stock

Kaolin Clay excavation |

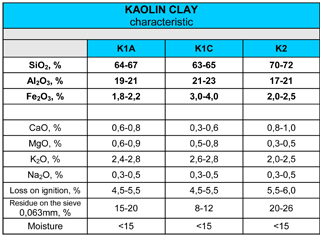

QUALITY CHARACTERISTICS

Structure according to petrographic mineralogy

Minerals |

Weight in % |

kaolinite |

34 |

ilit |

20 |

montmorionite |

10 |

quartz |

25-30 |

feldspaths |

5 |

Compared to other ceramic clay mines, this one has extraordinary favorable mineral structure, which includes three clay minerals.

Chemical structure

CONCLUSION

Based on test results, the conclusion is that this is a clay that sinters relatively low.

The mineral structure shows presence of kaolinite, ILIT and montmorionite as well, which is a rare case in our country - considering the clays known so far to be dominantly ilitic.

Due to the mineral structure, the percentage of Al2O3 is relatively high, which affect the fireproof ability of this clay. Based on these features, this clay can perform in ceramic masses as a component that reduces the sensitivity during the baking process and stabilizes the ceramic mass during the technologic production.

Dried Kaolin Clay |